If you are looking to add a personal touch to your metal projects, laser engraving is an excellent option. With a few simple steps, you can create beautiful designs that will last long term. In this guide, we will outline the basics of laser engraving and provide you with step-by-step instructions on how to get the best results.

Laser engraving metal is expensive and requires a lot of preparation

Laser engraving metal can be done by anyone with a laser cutter and some practice.

Today lasitlaser guide will teach you everything you need to know about laser engraving metal, including how to prepare for it and how to use the machine.

1. Get your Supplies Ready

In order to get the best results from your laser engraving machine, you need to use the right supplies.

The first thing you need is a piece of metal that is big enough to work with. You can use a variety of metals, including brass, copper, aluminum, and steel. The type of metal you choose will determine the results you get.

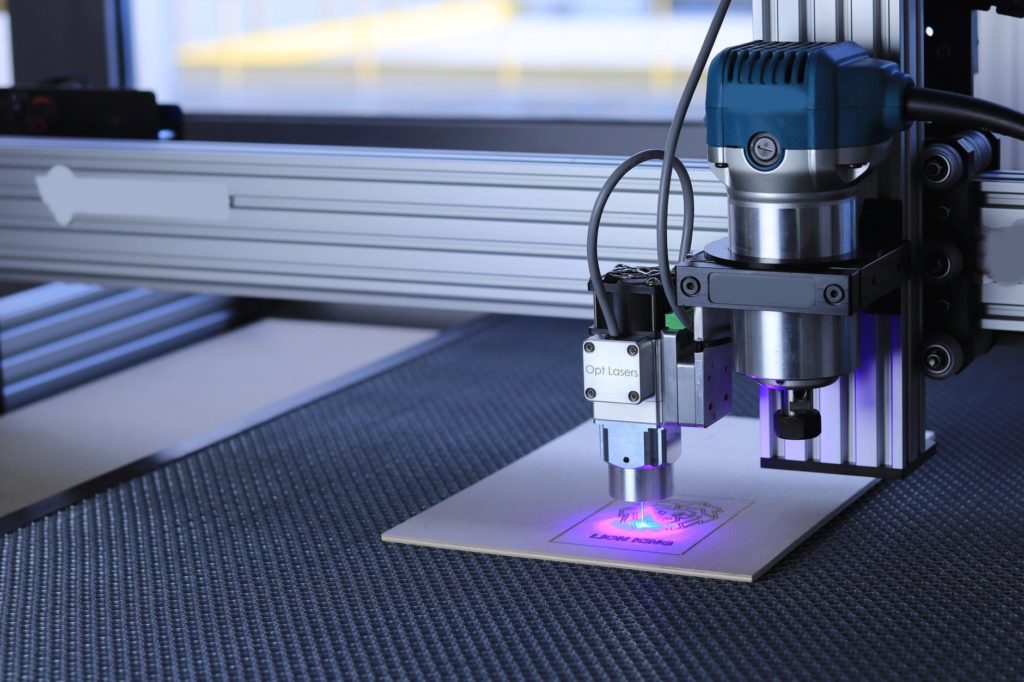

You also need a laser engraving machine that is powerful enough to engrave metal. Most standard lasers are not strong enough to do this, so you will need to invest in a high-powered machine.

2. Mark your Design on the Metal

Metal is a great material to laser engrave. It can be marked with very intricate designs that are both beautiful and permanent. The laser beam melts the surface of the metal, creating a smooth, shiny finish.

While it is possible to laser engrave many different types of metals, some are better suited for this process than others. Steel and aluminum are two of the most popular metals for laser engraving because they are durable and easy to work with.

3. Create the Engraving Area

The laser engraving process begins by creating the desired engraving area on the metal surface. This is done by carefully controlling the laser beam so that it only affects the surface of the metal and does not penetrate below the surface. The intensity and duration of the laser beam are also carefully controlled to achieve the desired results.

4. Engrave the Metal

The ability to laser engrave metal is a process that has been used for many years. It is a process that allows for an image or text to be engraved into the surface of a metal object.

The laser engraving process can be used on a variety of different metals, including gold, silver, and copper. There are a few different methods that can be used in order to create the desired effect.

5. Finish up and Admire your Work!

Not too long ago, the only way to get a nice, clean etching on metal was with a chemical process. This process could be time consuming and difficult to control, which often resulted in botched pieces.

Thankfully, technology has come a long way and now there’s a much simpler (not to mention faster) way to etch metal – laser engraving.

Laser engraving is a quick and easy way to add text or designs to metal surfaces. The laser beam is focused on the surface of the metal, creating a small point of intense heat. This heat causes the surface of the metal to vaporize, leaving behind a clean and crisp etching.

The best part about laser engraving is that it’s totally customizable. You can choose from a variety of fonts and designs, or create your own unique design.

How Much Does a Laser Marking Machine Cost?

Laser marking machines come in a wide range of prices, depending on the power of the laser and the features of the machine. Low-power lasers can be purchased for as little as $100, while high-powered lasers can cost tens of thousands of dollars.

Most laser marking machines include some basic features, such as the ability to mark text, graphics, and barcodes. More advanced machines can also mark serial numbers and product codes. Additionally, some machines have the ability to mark different materials, including metals, plastics, and glass.

Before purchasing a laser marking machine, it is important to consider what you will be using it for. If you only need to mark a few items occasionally, a low-power laser may be sufficient. However, if you need to mark large quantities of items regularly, you will need a high-powered laser with more features.

Final Thoughts

In conclusion, laser engraving is a great way to personalize metal items. It is a quick and easy process that can be done at home with a few simple supplies. By following the steps in this guide, you can create your own beautiful laser-engraved pieces.